Understanding the Technical Specifications of Best Multi Ply Labels and How to Choose the Right One for Your Needs

In today's competitive market, understanding the technical specifications of Multi Ply Labels is crucial for businesses aiming to enhance their product packaging and branding.

According to a recent report by the Pressure Sensitive Tape Council, the demand for advanced labeling solutions, including Multi Ply Labels, has seen a significant increase, with the market projected to grow at a CAGR of 4.5% through 2026. These labels, which offer multiple layers for printing and functionality, are not only versatile but also provide businesses with opportunities to convey more information and enhance visibility.

Choosing the right Multi Ply Labels can impact product presentation and consumer perception, making it essential for brands to carefully assess their specific needs and technical features before making a decision.

This article will serve as a comprehensive checklist, guiding you through the essential factors to consider when selecting the ideal Multi Ply Labels for your requirements.

Understanding Multi-Ply Labels: Key Technical Specifications You Should Know

When selecting multi-ply labels, understanding key technical specifications is crucial to ensure that they meet your specific requirements. Multi-ply labels consist of multiple layers, allowing for more information to be included and offering improved durability. According to the Label Industry Global Scenario 2021 report, the multi-layer label market is experiencing a steady growth rate of approximately 5% annually, indicating a rising demand for complex labeling solutions that can withstand environmental stressors.

One pivotal aspect to consider is the adhesive type used in multi-ply labels. As highlighted in the 2022 Label Adhesives Report, the choice of adhesive can significantly affect performance under various conditions such as temperature and humidity, which can impact the label's adhesion to surfaces. Furthermore, the materials used in the layers, such as paper, film, or foil, also play a critical role in defining the label’s strength and flexibility. For example, polyester film, often used for durability, can enhance resistance to tearing and moisture, making it an ideal choice for products that encounter harsh conditions.

Moreover, the printing method applied to multi-ply labels is another technical specification that influences overall quality. Digital printing has surged in popularity, accounting for more than 30% of label production as noted in the 2023 Label Printing Trends report, due to its ability to produce high-quality, customizable labels with lower setup costs. Understanding these specifications allows businesses to choose the right multi-ply label that align with their packaging needs and market demands.

Multi-Ply Labels Specifications Comparison

This chart compares the key technical specifications of various multi-ply labels, including material strength, tear resistance, and adhesive quality. Choosing the right label involves understanding these factors as they impact durability and performance in different applications.

The Role of Material Quality in Determining Label Durability and Performance

When it comes to selecting multi-ply labels, the quality of materials plays a crucial role in their durability and performance. According to a recent industry report by Smithers Pira, high-quality label materials can enhance resistance to moisture and chemicals, resulting in labels that last longer in challenging environments. Materials such as BOPP (biaxially oriented polypropylene) and high-grade paper are often preferred for their enhanced durability, making them ideal for products that will be stored outdoors or in refrigerated conditions.

When choosing the right label, consider the specific application and environmental factors. For instance, if your product will be exposed to extreme temperatures or water, opting for a weather-resistant label can prevent premature degradation. Additionally, a recent survey by Label Insight found that 69% of consumers check product labels for information before making a purchase, highlighting the importance of clear and durable labeling in influencing buying decisions.

**Tips:** Always request samples of labels to test their resistance to typical conditions they will face. Additionally, verify if the manufacturer provides any certifications for their materials, which can serve as a good indicator of quality. Lastly, choose a label that aligns with both your product requirements and customer expectations to ensure satisfaction and compliance.

Understanding the Technical Specifications of Best Multi Ply Labels and How to Choose the Right One for Your Needs

| Label Type |

Material Quality |

Durability |

Performance Features |

Best Use Case |

| Standard Multi Ply |

Paper with laminate |

Medium |

Water-resistant, moderate tear resistance |

General labeling |

| Synthetic Multi Ply |

Polyester |

High |

UV resistant, extreme durability |

Outdoor use |

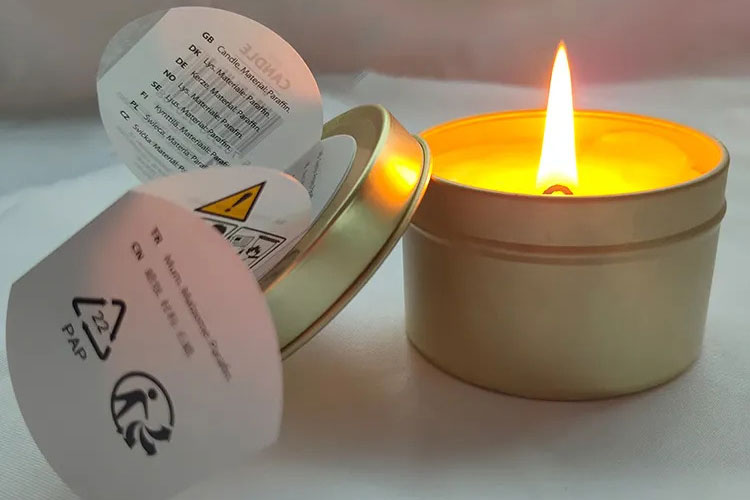

| Safety Multi Ply |

Vinyl |

Very High |

Chemical resistant, high visibility |

Hazard warnings |

| Custom Multi Ply |

Eco-friendly paper |

Medium |

Printable, good adhesion |

Promotional purposes |

| Industrial Multi Ply |

Polypropylene |

High |

Oil and water resistant, rugged |

Manufacturing and logistics |

Printing Techniques for Multi-Ply Labels: Ensuring Clarity and Precision

When it comes to printing techniques for multi-ply labels, clarity and precision are paramount. According to a report by Smithers Pira, the demand for high-quality label printing is projected to grow at a CAGR of 3.9% from 2021 to 2026. This growth emphasizes the need for advanced printing methods that not only enhance visual appeal but also ensure the accurate reproduction of complex designs and texts. Techniques such as digital printing and flexography are leading the way, offering impressive results that cater to both small and large-scale production.

Digital printing technology, in particular, stands out due to its ability to produce high-resolution labels with sharp images and vibrant colors, while also accommodating customization in short runs. A study by the Label Manufacturers Association reveals that 70% of label consumers prioritize print quality, identifying it as a key factor in their purchasing decisions. Flexographic printing, known for its speed and efficiency, also maintains low production costs for long-run projects, making it an ideal choice for manufacturers aiming for balance between quality and cost-effectiveness. By understanding these printing technologies, businesses can select the best multi-ply labels that cater to their specific needs while ensuring that the end product showcases the desired clarity and precision.

Digital printing technology, in particular, stands out due to its ability to produce high-resolution labels with sharp images and vibrant colors, while also accommodating customization in short runs. A study by the Label Manufacturers Association reveals that 70% of label consumers prioritize print quality, identifying it as a key factor in their purchasing decisions. Flexographic printing, known for its speed and efficiency, also maintains low production costs for long-run projects, making it an ideal choice for manufacturers aiming for balance between quality and cost-effectiveness. By understanding these printing technologies, businesses can select the best multi-ply labels that cater to their specific needs while ensuring that the end product showcases the desired clarity and precision.

How to Evaluate Adhesive Options for Various Applications of Multi-Ply Labels

When selecting multi-ply labels, one of the most critical aspects to consider is the

adhesive options available for various applications. Different environments and surfaces

require adhesives that can perform reliably under specific conditions. For instance, if you

are labeling products that will be exposed to moisture or extreme temperatures, a waterproof adhesive

may be necessary. These adhesives are designed to maintain their bond under adverse weather

conditions, ensuring that your labels stay intact and legible.

Another factor to keep in mind is the surface material where the label will be applied.

Smooth surfaces, like plastic or metal, often require a different type of adhesive than rough

or porous surfaces, such as cardboard or wood. Choosing the right adhesive will help

prevent issues like peeling or fading, which can detract from the label's effectiveness.

It's also essential to consider whether a permanent or removable adhesive

is more suitable for your application based on how long you intend to keep the labels in

place. By evaluating these adhesive options carefully, you can ensure that your multi-ply

labels meet your specific needs and perform consistently over time.

Cost-Effectiveness and Sustainability: Choosing the Right Multi-Ply Label for Your Needs

When selecting multi-ply labels, cost-effectiveness and sustainability are two essential factors that can significantly influence your decision. Cost-effectiveness goes beyond the initial purchase price; it encompasses long-term durability, functionality, and the potential for reduced waste. High-quality multi-ply labels may require a higher upfront investment but can lead to savings through decreased product returns and improved customer satisfaction. Evaluating the total cost of ownership rather than just the sticker price will ensure that you are making a financially sound choice.

On the sustainability front, choosing eco-friendly materials can greatly impact your brand’s environmental footprint. Opting for labels made from recycled or biodegradable materials not only reflects corporate responsibility but also appeals to eco-conscious consumers. It's crucial to consider the entire lifecycle of the label, from production to disposal. By selecting labels that minimize environmental impact, you contribute to a more sustainable future while enhancing your brand image. Balancing these factors will help you choose the right multi-ply label that meets both your budgetary requirements and your sustainability goals.